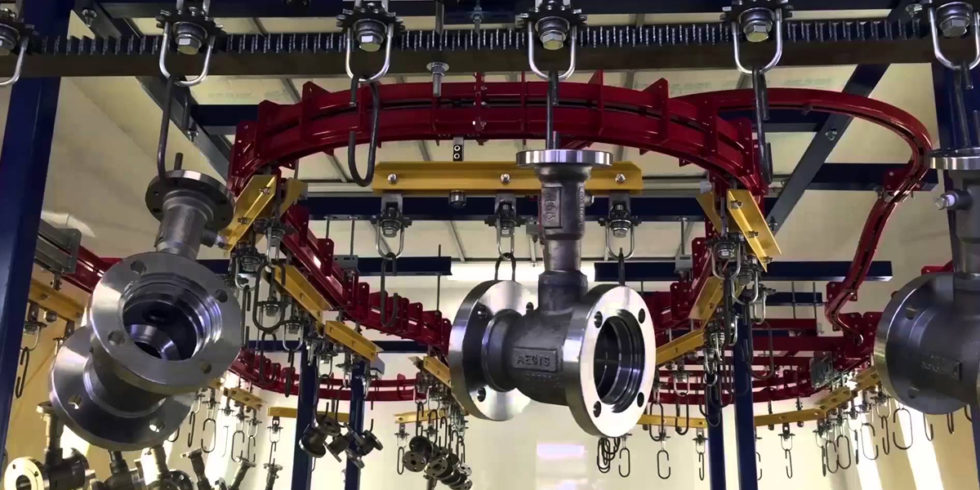

Power & free conveyor system for painting line is consised of before trolley+behind trolley+before trolley+behind trolley. Installing a before shovel in before trolley, and connected to the lifting claw through the coupling mechanism. Behind shovel is installed on behind trolley. When the product is required to do power&free, pneumatic stop be opened, will button lifting claw in trolley before 1 trolley group, to release push on the drag chain. Trolley 1 group stop running, trolley 2 go on running forward, until the before shovel of before trolley along slope in behind trolley behind shovel of trolley 1 group lifting. It will let lifting screw decline and come away drag chain. Trolley 2 group stop running, the analogy of later trolley group. When end of power&free work, pneumatic stop closing, lifting screw on the front of the trolley 1 group raised by the weight of the before shovel itself. Push of traction chain in position to push the trolley 1 group running forward. As the forward running of trolley 1 group, before shovel of trolley 2 group come away behind shovel of 1 trolley, lifting screw raise, achieve power&free work.

Running method

Trolley stop or running and will not interfere with each other in normal running. Conveying workpiece can be stored on painting line. A longer workpiece can be used in a parallel power&free or oblique power&free. According to different regions can achieve different partition of workpiece, a line of different speed can be set up according to the different location.

Proposal description

Power &f ree suspension conveyor arranged along the launch point in the welding workshop. Welding workshop production parts hanging according to the type of coating group hanger model, transport to do surface treatment in coating production line directly after hanging.

Advantage

Empty hook can realize prior distribution of different loading location according to coating workshop production arrangement, satisfy the coordination between the different location.

It doesn’t have secondary turn hang and connect with the conveying directly, so workpiece in better protection, no human waste.

Loading area without lots of workpiece which be in store, save land for workshop.

Equipment costs and labor costs can achieve balance in production after a certain period of time, this part of the investment of equipment in the later period of production for profit.