A pretreatment system is used for large products, and also for productions with small quantities or limited space.

If the geometry of the product, e.g. in the automotive industry, is complex and if a spray system cannot reach all surfaces of the product, this type of pretreatment is the best choice.

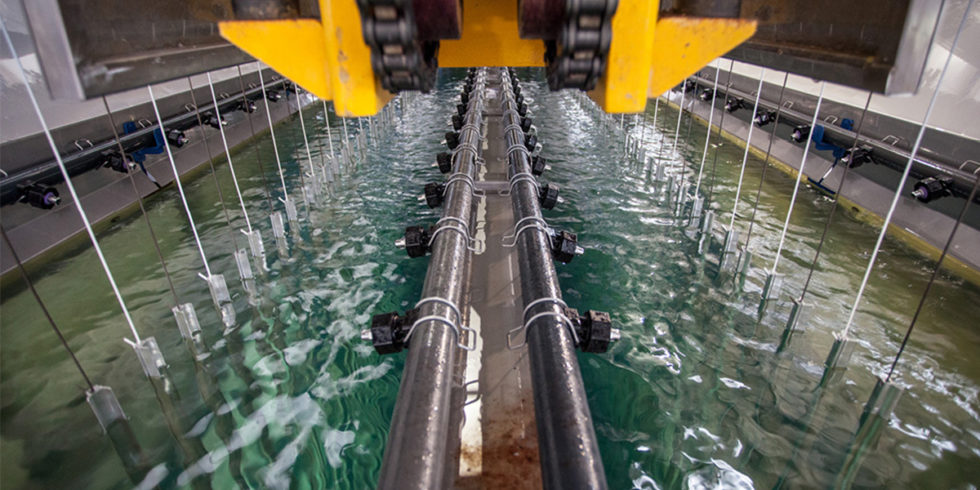

The dip tank pretreatment design is customized on the basis of the product. We design the number, the size as well as the temperatures according to the chemical process.

The tanks are normally made of 2 mm stainless steel. A very strong steel construction with a cradle like function supports the sides of the tanks. The heated tanks are insulated with 75 mm mineral wool and covered with powder painted cassettes on the outside; alternatively galvanised or plates unpainted.

The design includes pre- and after rinse systems which are electronically controlled and ensure a minimal consumption of water, energy and chemicals.

The dip pretreatment is very important before powder coating, paint coating, e-coating.